MES

What is MES?

This is the Manufacturing Execution System that continuously manages and monitors the entire process from material warehousing to production and product release, and manages manufacturing-based production. Standard information management

Standard information management Production plan management

Production plan management Quality control

Quality control Product warehouse management

Product warehouse management Production Tracking and History Management

Production Tracking and History Management Maintenance Management

Maintenance Management Report

Report System interface

System interface

Functional composition

Standard information management

- Common code

- Standard information registration

- Bad code information

- Common code

- Non-operation code information

- Process equipment registration

Materials information management

- Materials receipt registration

- Materials release registration

- Materials location management

- Incoming material inquiry

- Details of materials release

Production management

- Work order information registration

- Actual output against work order

- Production performance management

- Production performance management

- Defect record inquiry

- Actual against plan inquiry

- Non-operation inquiry

- Production aggregate by period

- LOT TRACKING

Delivery management

- Delivery record registration

- Delivery details inquiry

Start-middle-end management

- Inspection item registration

- Inspection item registration

- Results registration

Tooling management

- Tooling master management

- Tooling repair history

- Tooling inspection history

Inventory management

- Inventory status by label

- Inventory audit management

- Inventory status by item number

- Incoming/outgoing inquiry by month

System management

- User group and user registration

- Program information registration

- User group rights information registration

- User rights information registration

Monitoring

- Production performance monitoring

- Process status monitoring

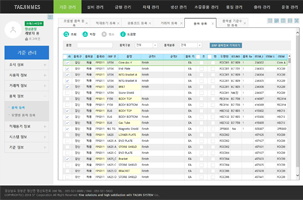

System Screen

기준관리

Facility management

Tooling management

Quality control

Production performance

Weight measurement

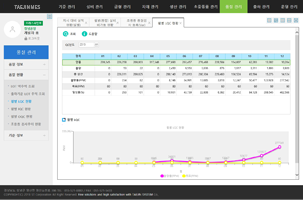

Performance status monitoring

Monitoring of monthly performance to plan